Industrial Stainless Steel Shaft High Precision Turned Parts Grinding Surface

Quick Detail:

Name | Machinery shaft | Material | Stainless steel ,etc |

Process | CNC lathe turning | Surface treatment | Grinding |

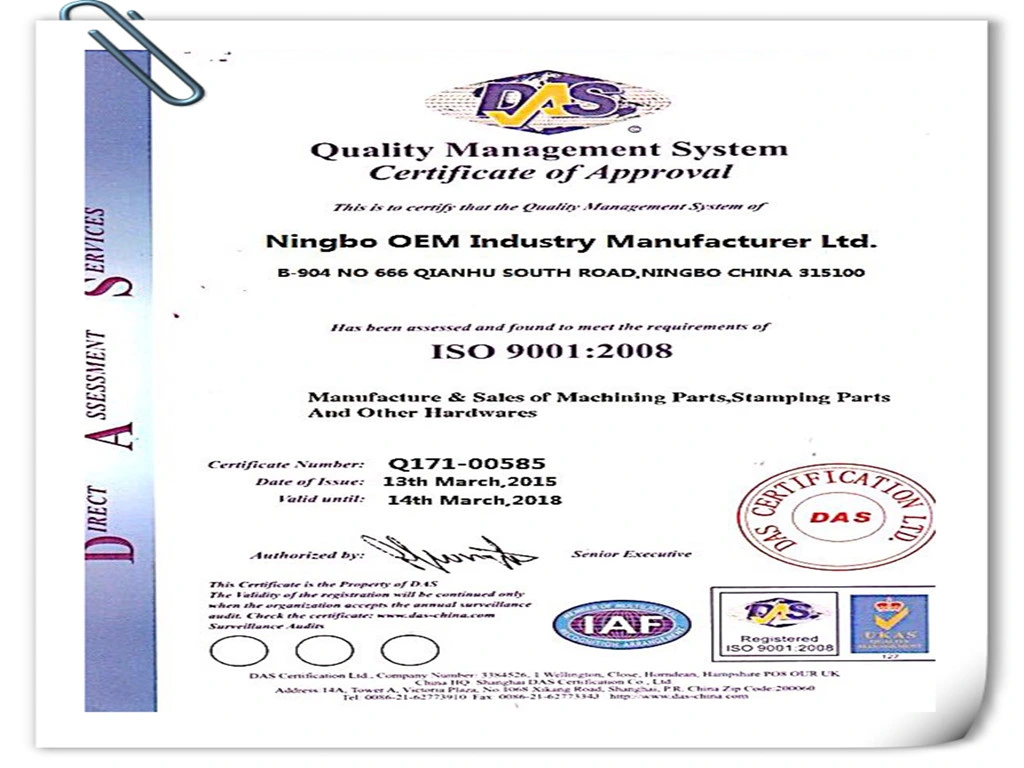

Application | Every industrial | Certification | ISO, SGS |

Description:

| Name | Machinery shaft ,stainless steel shaft |

| Size | Customized, according to drawings |

| Material | Carbon Steel, Alloy Steel, Stainless Steel, Aluminum, Brass, Zinc etc. |

| Accuracy | Accuracy Of Machining:+/-0.01mm |

| Accuracy Of Grinding:+/-0.01mm | |

| Surface Roughness:Ra0.8 | |

| Parallelism:+/-0.005mm | |

| Verticality:+/-0.005mm | |

| Concentricity:0.003mm | |

| Application | Automabiles, Motorcycle, Mechanical Equipment, Furniture,etc. |

| Drawing | JPEG, PDF, CAD, IGS, Step,Stp,X_t acceptable |

| Service | One Stop service for your project, supply aluminum profile, cnc parts, lathe parts, stamping parts, die casting mould and parts with surface treatment |

| Design | Design and improvement to meet your individual demands. |

| Quality | ISO9001/TS16949 Quality System Management Assurance |

| Payment | Various options to make payment more convenient. |

| Logistics | LCL to save your freight cost |

| Customer Service | 24-hours standby, Critical listening your every suggestion or demand and feedback ASAP |

Applications:

Parts are applied for:

- Defense, auotmotive, telecommunication, consumer electronics, appliances;

- Medical device, Lab equipments, food and beverage processing equipments,

:

Specification :

All the product pictures on our website just showing our machining capability and ranges We offer machining service according to customer's drawings or samples

1, Experience: more than ten years manufacturing history;

2, Price : Reasonable and competitive according to your drawings;

3, quality assurance: To ensure correct standard and choose equivalent stansard for materail and technique requirements,before running ,we would like to provide formal material certificate showing chemical compositions and property,also if you need ,we can provide control plan,showing processing and inspection tooling;

4, quanlity control: In house,coming inspection,first off,spotcheck in processing ,final inspection, 100% inspection for critical dimension;

5, Small order are accepted;

6, packing: carton box or iron can or depend on your requirements;

7, Delivery: 20-30days after confirming order, according to your requirements and production quantity:

8, Payment: By T/T, for samples 100% with the order: for production,50%paid for deposit by T/T before production arrangement, the balance to be paid before shipment. or negotiation;

9, honesty and professional services;

1) Material | SS304, Plain steel, Carbon Steel 1040 etc |

2) Finishing and Treatment | Polishing, grinding, |

3) Equipments involved | CNC machining/, CNC lathe, surface grinding machine etc |

4) Processes involved | CNC milling, turning, grinding etc |

5) Dimensional tolerance | ±0.02mm or less |

6) Geometric tolerance | ±0.05mm or less |

7) Roughness | Ra 0.016 or less |

8) Production capacity | 10,000pcs per month |

9) Quality inspection | IQC, PQC, FQC |

We provides custom CNC machining service for many years. Our trained staffs have extensive experience in quick prototype machining and precision machining. These valuable experience prove that we able to quick response to your needs of making the precision parts.

The custom machining services that we can offer:

CNC milling

CNC turning

Multi-axis milling and turning

Automatic lathing

Custom Machine Parts

Metal Stamping parts

Welding& solder

Metal fabrication

With our advanced Technology machines, established machining process management, and supporting supply chain in Ningbo, we are committed to ensure to complete your custom projects as below:

i. Within the timeframe,

ii. Within the budget,

iii. Meeting the quality standard.

In additional, NINGBO OEM INDUSTRY MANUFACTURER LTD. is able to provide value-added engineering service. We can assist you from material choosing, structure testing, process up to finished goods arrangement. Our goal is to provide one-stop custom machining services to our customers and establish long term relationship.

Materials Available for CNC Machining:

| Materials Available | Stainless Steel | SS201, SS303, SS304, SS316 etc. | |

| Steel | Q235, 20#, 45# etc. | ||

| Brass | C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37) , C28000(CuZn40) | ||

| Iron | 1213, 12L14,1215 etc. | ||

| Bronze | C51000, C52100, C54400, etc. | ||

| Aluminum | Al6061, Al6063,AL7075,AL5052 etc | ||

| Terms and Conditions | |||

| Our Processing | CNC machining, CNC milling and turning, drilling, grinding, bending, stamping, tapping, injection | ||

| Surface finish | Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, imitation gold-plated, | ||

| Tolerance | 0.05mm~0.1mm | ||

| QC System | 100% inspection before shipment | ||

| Drawing format | CAD / PDF/ DWG/ IGS/ STEP | ||

| Packaging | Standard package / Carton box or Pallet / As per customized specifications | ||

| Payment Terms | 100% T/T or Western Union in advance | ||

| Trade terms | EXW, FOB, CIF, As per customer's request | ||

| Shipment Terms | 1) 0-100kg: express & air freight priority 2) >100kg: sea freight priority 3) As per customized specifications | ||

| Note | All CNC machining parts are custom made according to customer's drawings or samples, no stock. If you have any CNC machining parts to be made, please feel free to send your kind drawings/samples to us anytime by email. | ||

Specifications:

Technical Parameter for RF Connector Customise Fine Surface Precise Aluminium CNC Milling Parts | Length x Width x High | 5X5 X5 mm ~ 500X500X500mm |

Tolerances | +/- 0.005mm | |

Material use | Aluminium, Copper, Brass, Stainless Steel | |

Processing | CNC Machining Center | |

Surface Treatment | Galvanized, electro-plating, conversion coating,Zinc plating, or chrome plating available | |

Surface Roughness | Ra0.4a | |

Run-out | 0.005mm | |

Flatness | 0.005mm | |

Perpendicular | 0.005mm | |

Cylindricity | 0.005mm |

Description | Types |

Competitive Advantage |

|

Total Solution Provider |

|

Our Winning strategy |

|

Application Industry |

|

Equipment display:

| Process Facilities | Quantity |

| CNC milling machine | 3 sets |

| Cnc Lathe Machine | 32sets |

| Lathe machine | 3 sets |

| Grinding Machine | 2 set |

| Surface Grinding Machine | 2 sets |

| Drilling Machine | 5 sets |

| CNC Milling Machine | 1 sets |

| Drilling And Milling Machine | 2 sets |

| Automatic Tapping Machine | 6 sets |

| Punching Machine | 10 sets |

| Four Column Hydraulic Press | 1 set |

| Plastic Injection Machinery | 2 sets |

| Laser marking Machine | 1 set |

| Air-blow logo marking set | 1 set |

| Watertight leakage tester | 2 sets |

Testing Machinery:

| Machine Name | Quantity |

| Rockwell-hardness-tester | 4 |

| Height gauge | 1 |

| Universal tools microscope | 1 |

| Projector | 1 |

| Gear testing center | 2 |

| Metallographic microscope | 1 |

| Three coordinates measuring instrument(CMM) | 1 |

| Microcomputer controlling tester | 1 |

| Roughness tester | 1 |

| Mechenical property tester | 1 |

| Impact strength tester | 1 |

| Japanese mitutoyo digital caliper | 3 |